Nathan Selian: Mechanical Engineering

Morphing Sails for Maritime Shipping - Senior Design

For my senior capstone project, my team and I designed a morphing sail system to provide wind-assisted propulsion for cargo ships. The goal was to reduce fuel consumption and carbon emissions while maintaining reliability, autonomy, and cost-effectiveness.

Inspiration

When I started my senior design project at Boston University, I knew I wanted to work on something that mattered beyond the classroom. Our team was drawn to a challenge with global impact: reducing emissions from cargo shipping. Ships move a staggering amount of the world’s trade goods, but they also produce a massive share of global CO₂. In recent years, shipping companies have slowed vessels down to conserve fuel, but that solution isn’t sustainable for efficiency or the economy.

The question we asked ourselves was simple but ambitious:

What if modern ships could once again harness the wind?

Sailing ships carried goods for centuries, but modern cargo vessels abandoned sails in favor of fossil fuels. With new materials, aerodynamic analysis, and autonomous control systems, we saw an opportunity to bring sails back — not in their old form, but in a new, adaptive design that could seamlessly integrate with existing ships.

Two of our teammates, including me, came from the BU sailing team. We understood firsthand how sails work, how critical trim and camber are, and how small optimizations can mean the difference between winning a race or standing still. That passion shaped the project from day one.

Understanding The Problem

One of the easiest traps for engineers to fall into is jumping straight to a solution. We’re problem solvers at heart, so the instinct is immediate: see an issue, sketch an idea, start building. But over time we learn that good engineering isn’t about the speed of the solution, it’s about the quality of the problem definition.

When our team was first handed the challenge of reducing emissions from cargo ships, the temptation was to dive right into exotic sail designs, high-tech materials, and futuristic renderings. But before we allowed ourselves to brainstorm, we stepped back and asked: what exactly is the problem we’re solving, and how do we frame it in a way that engineers can attack it?

That meant:

-

Defining the scope. Shipping isn’t a niche sector — it’s the backbone of global trade. A “solution” that works only on a small vessel or in idealized conditions would never scale. We needed something retrofit-friendly, globally deployable, and practical for crews who may not be specialized in sail handling.

-

Identifying key parameters and challenges. On paper, the problem is “too much fuel use, too many emissions.” But what matters technically? For us, it boiled down to fuel savings, emissions reduction, operational reliability, air draft (clearance under bridges), and cost effectiveness. These became the levers we could model and design around.

-

Simplifying without oversimplifying. Cargo ships are incredibly complex systems, but to make progress we reframed the challenge in aerodynamic terms: lift, drag, camber, angle of attack. By anchoring the problem in these controllable variables, we could turn something daunting and abstract — “cut global emissions” — into something tractable and measurable.

-

Considering the human factor. We also asked: what would this feel like for a crew? A sail system that required constant trimming and monitoring would never be adopted. That led us to autonomy and self-adjusting mechanisms as a requirement, not a luxury.

This careful front-loading of research and framing wasn’t glamorous, but it was essential. It kept us from chasing shiny ideas and instead gave us a clear design target: an autonomous, adaptable sail that balances aerodynamic performance with real-world integration.

The Design

Once we had framed the problem and defined the scope of our project, the next step was to decide how to approach a solution that was both technically ambitious and realistically achievable within a capstone. That meant splitting our design into two parallel tracks:

The Paper Design (full-scale concept).

This was our answer to the overarching problem: How can wind-assist technology cut emissions for real cargo ships? We analyzed existing concepts like Flettner rotors, wing sails, and inflatable designs, and ultimately chose a sectioned-airfoil sail with a mid-chord split to allow hydraulic camber adjustment. Angle of attack and camber would be autonomously controlled, ensuring the sails continuously optimized themselves without crew intervention.

Configuration: eight sails retrofitted to bulk carrier or tankers.

Materials: lightweight aluminum structure with a UV-resistant composite skin.

Performance: calculations showed a 37% reduction in emissions, surpassing the 30% industry target.

The paper design gave us a concrete, defensible solution to the big-picture shipping challenge.

The Scale Model (capstone prototype).

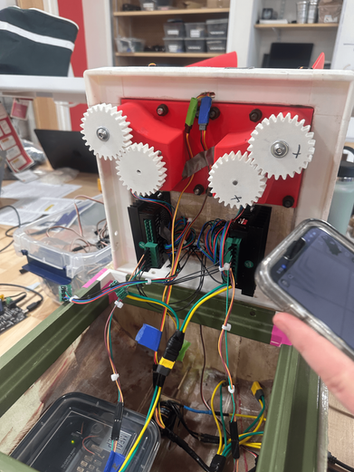

To validate aspects of our paper design, we developed a smaller-scale prototype on a $500 budget. The goal wasn’t to perfectly replicate full-scale behavior, but to demonstrate key functions — camber adjustment, angle-of-attack control, and autonomous response to changing wind conditions.

Testing Plan: dry testing at BU’s EPIC and RASTIC facilities, followed by wet testing on the Charles River.

Focus: prove the feasibility of the morphing mechanism and control system, rather than raw aerodynamic performance.

The prototype ensured our project wasn’t just a thought experiment. It was something we could physically build, measure, and iterate on, while still tying back to the global challenge.

By pairing these two approaches — conceptual breadth and prototype depth — we created a project that addressed both the ambition of real-world impact and the practicalities of a student design lab.

My Role

My contributions to the project reflected the two parallel tracks we pursued: the full-scale paper design and the scale prototype.

On the Paper Design side:

My biggest contribution was bringing in my sailing knowledge. Having spent most of my life sailing, I was able to translate a complex shipping challenge into simple, effective terms: lift, drag, camber, and angle of attack. This perspective helped our team frame the problem in a way that engineers could model and solve, while keeping the design grounded in how sails actually perform on the water. I also contributed heavily to the competitive benchmarking and trade studies, but my role here was mainly about shaping the problem definition and ensuring our concept stayed true to real sailing principles.

On the Scale Model side:

I led the charge in the mechanical design and build. I designed nearly all of the components in CAD, making sure the prototype mechanisms mirrored the logic of our full-scale concept. Over the course of one weekend, I built the hull from fiberglass and epoxy, giving us a rough but durable platform for testing. I also assembled and installed most of the components, integrating structure, actuation, and controls into a working prototype.

This dual role — problem framing through sailing expertise and mechanical execution through hands-on building — gave me the chance to apply both sides of my engineering identity. It also pushed me to constantly think about how theory and practice inform one another, ensuring that our design wasn’t just an academic exercise, but a project we could actually test, refine, and learn from.

Why it Matters - Big Takeaways

At first glance, our project was about designing a new kind of sail. But really, it was about learning how to approach a massive, complex problem with both ambition and humility.

By starting with the problem, we resisted the urge to jump straight to flashy ideas. Instead, we defined the scope, identified the key parameters, and framed the challenge in terms we could model and test. That mindset led us to a full-scale paper design — a concept capable of cutting shipping emissions by 37%, showing the potential impact wind-assist technology could have on global trade.

At the same time, we acknowledged the limits of a capstone project. We couldn’t retrofit an oil tanker, but we could build a scale prototype to validate our ideas. That model forced us to make things real: design parts in CAD, lay up fiberglass for a hull, install actuators, sensors, and actually watch a morphing sail respond to wind.

The strength of the project came from balancing both tracks: the ambition to think big, and the discipline to build small.

For me personally, this project mattered because it blended two worlds I care deeply about: sailing and engineering. I got to bring my sailing knowledge to the problem definition, and then roll up my sleeves to design and build the prototype. It reinforced that good engineering is as much about framing problems and making trade-offs as it is about creativity or analysis.

Most of all, it showed me that even as students, we can meaningfully contribute to big challenges like sustainability. The path from concept to real-world solution is long, but it starts with projects like this — where ideas, prototypes, and passion collide.